You learn so much when visiting prospective new clients face to face and why the online and phone calls plays a role, but can never replace human contact. Over the last month and a bit we have been communicating via email and made samples according to what was discussed. They order by the kilogram which is not a standard or normal procedure and my guess is they have been screwed over before or if not then being screwed over now.

I had not been supplied the quantities they use monthly, but the samples requested showed a manual type packaging operation so in my head I had thoughts of maybe 3 pallets per month which is 1.5K rolls of pallet wrap with each one being 400m the standard length. This would be a decent account worth in the region of around $500 monthly going into my pocket. A good result for 6 weeks work except the samples were wrong in a good way because they do use machine wrappers and nothing is manual. Crucial information which tells me they do not handle the product or have worked with it themselves.

The two people I had been emailing back and forth are at least doing their jobs, but have no understanding of exactly what they are ordering and negotiating. This is kind of normal with a family owned company where people wear different caps covering many positions. Who is to argue this does not work as they have been around for 80 years and are the last textile blanket company in the country with the Chinese having destroyed all the other competitors. They are not only the last ones standing and super busy, but from what I witnessed they are thriving.

I asked for a quick tour so I could understand what they are doing and see how my packaging wrap would be used using whatever applications they had. There was a giant yarn store which whilst walking through doing some quick calculations must have over 1000 pallets of stock. I did not see the manufacturing process as this was in another building, but did see the automated pallet wrap machines which there was many. Most warehouses have one so having multiple in this case tells you how busy they become in their seasonal periods.

During the walk I was always asking questions because I need to know the quantity of supply so I can best offer a solution to service their needs. Guess work helps no one and needed to know problems they have encountered in the past so as to be prepared to handle their problems as they would become my problems. You need to know how well organized or unorganized they are from the off so you are the solution. They apparently run out often and that means me holding stock which we are prepared to do and being on call 7 days a week if required.

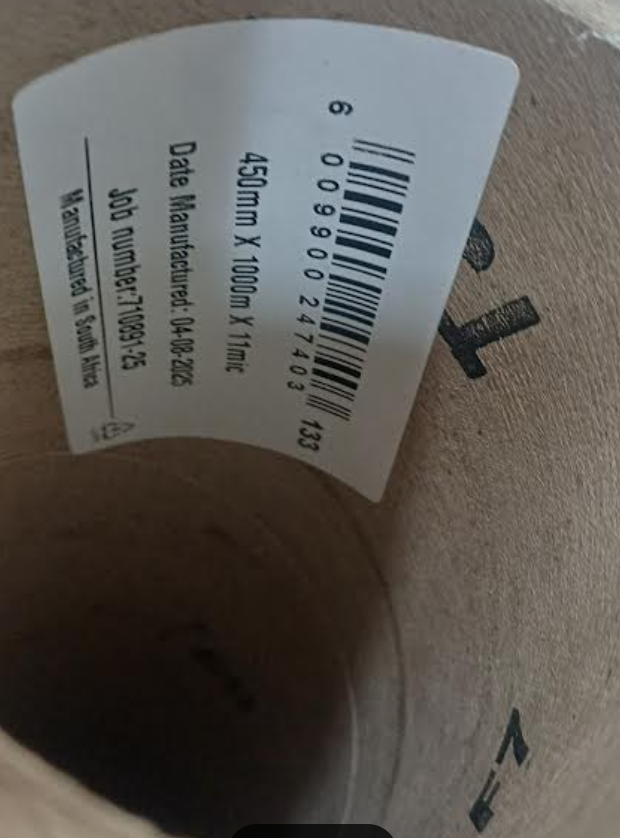

It turns out they order 1000 machine rolls monthly which are 1000m in length and found that out by finding a suppliers barcode and product description in the middle of the core. This is basically double the volume I had expected due to not being informed correctly. Before I had visited I was confident the information they had given me was correct even if it was a little vague and was not in meters and kilograms.

Sometimes having people in buying positions who do not know the product benefits you the supplier and you can see why companies can be taken advantage of by those with no morals. Maybe I am over thinking this , but again the numbers do not add up to the business volume I witnessed against the usage and need to return and weigh the cardboard cores. An extra heavy core will give them less product volume meaning their usage is higher than it really is and where the current supplier is ripping them off.

Posted Using INLEO