3D printing is an amazing hobby and most of the time PLA prints work fine for me but every now and again I need something with a bit more strength. I’ve printed with ABS in the past, but I thought I’d give nylon a go as I need some parts printing to attach a bike rack and unfortunately my bike does not have any built in rack lugs.

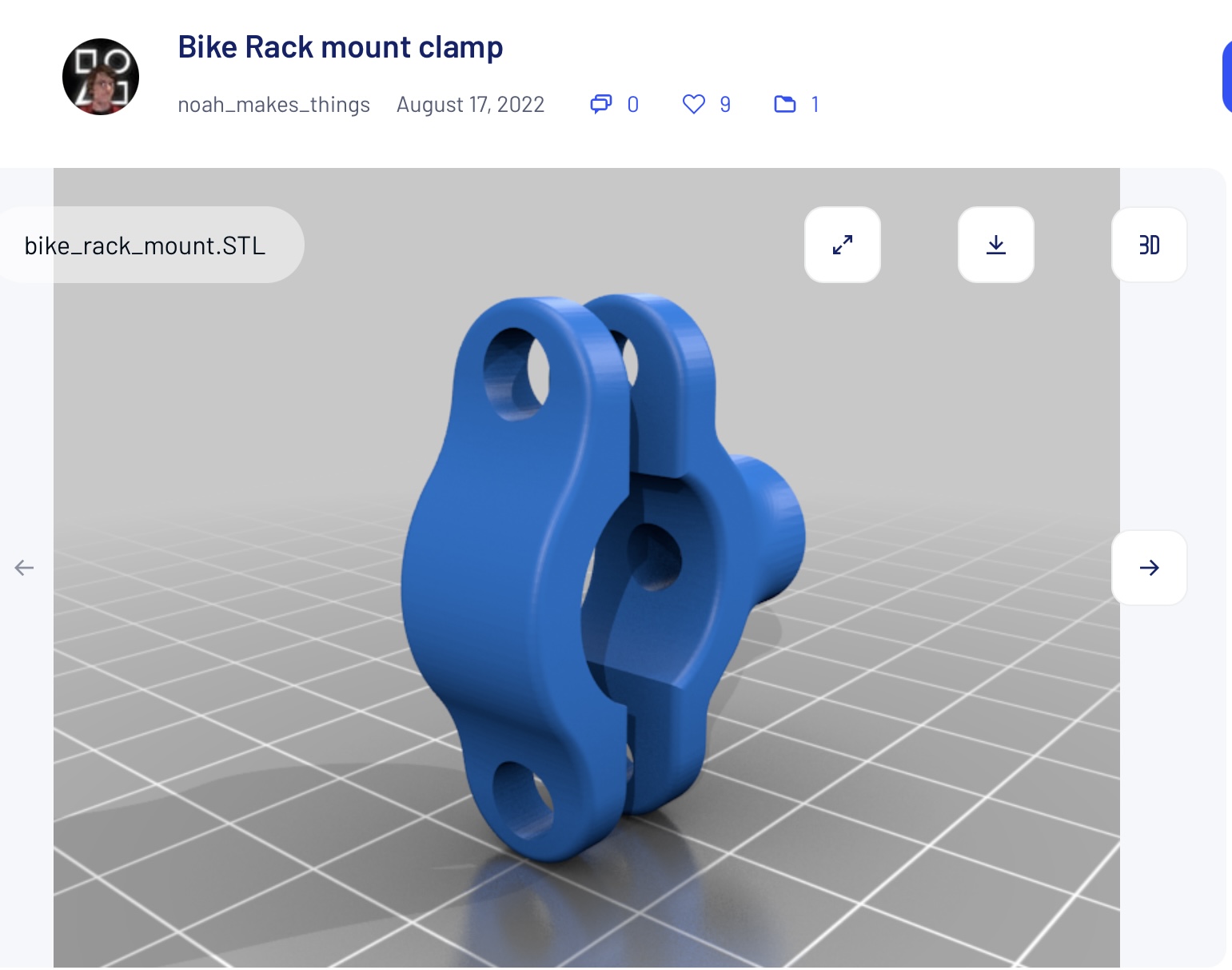

Once again Thingivers is my friend as usual someone has been here before so STL files are already there.

Printing with nylon has a couple of issues OK more than a couple the main one being moisture so you really need a print dryer to cook the filament and store it during the print. I did try without once and and even the brand new filament sounded like popcorn going off when it started. So a dryer is a must have.

Even after drying the roll for 6 hours the first few layers of the print sounded like popcorn going off as the moisture in the filament popped off to steam as it went through the hot end. Running the filament straight out of the heater is helping and the popping stopped after the first few layers so it must have been just the end few centimetres.

The next thing to tackle is bed adhesion I use a PVA/water wash on the bed to help a bit with this it seems to work and a brim for the parts helps too.

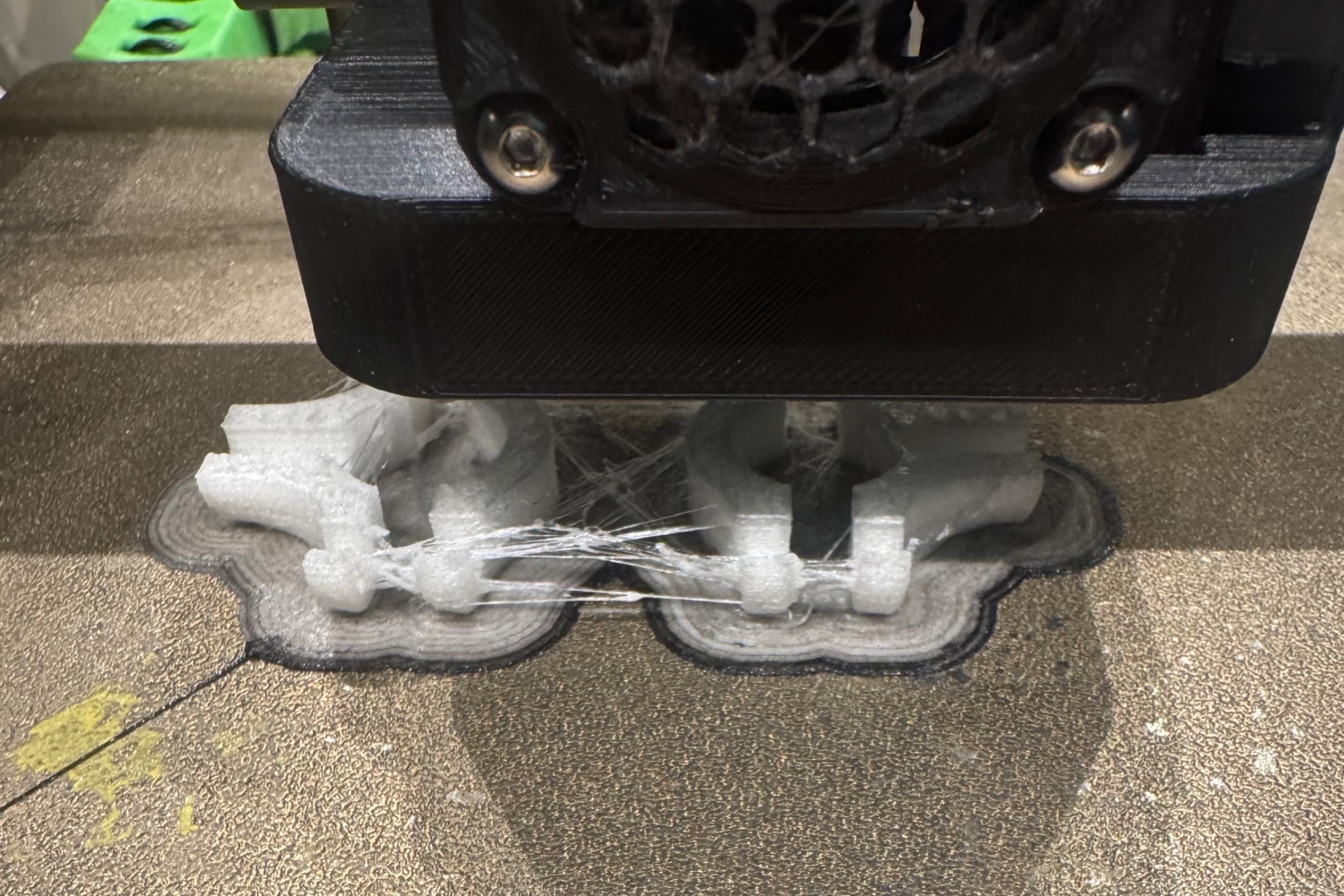

The first print is stringing quite a bit which is another common problem so I’ll need to tweak the slicer setting a bit to try and improve that. I think the best bet is slowing the print speed down to around 30 mm/s it’s set around 50mm/s as a default at the moment which I think is a bit quick. The hot end and bed temperatures seem fine.

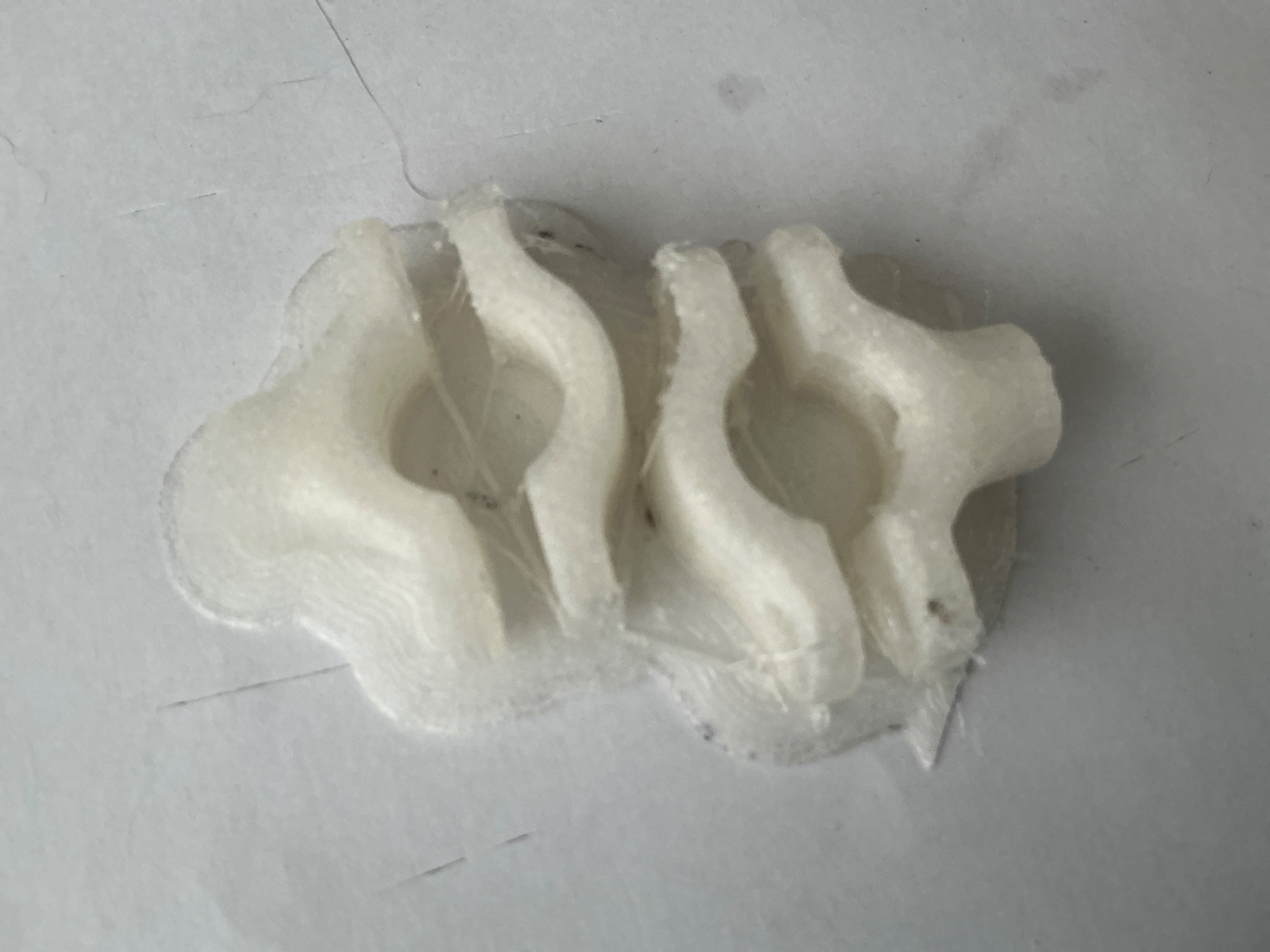

There we go that looks like a much better print still a little bit of straining but much better. Not bad on a standard Ender 3 printer that is about 8 years old now, I should upgrade but the Bambu Labs one I want with a multi filament feeder is over £1500 so I guess it can wait.

.

.

So Hivers in the end the parts turned out OK with only a little bit of stringing on the base few layers which should be easy enough to clean up