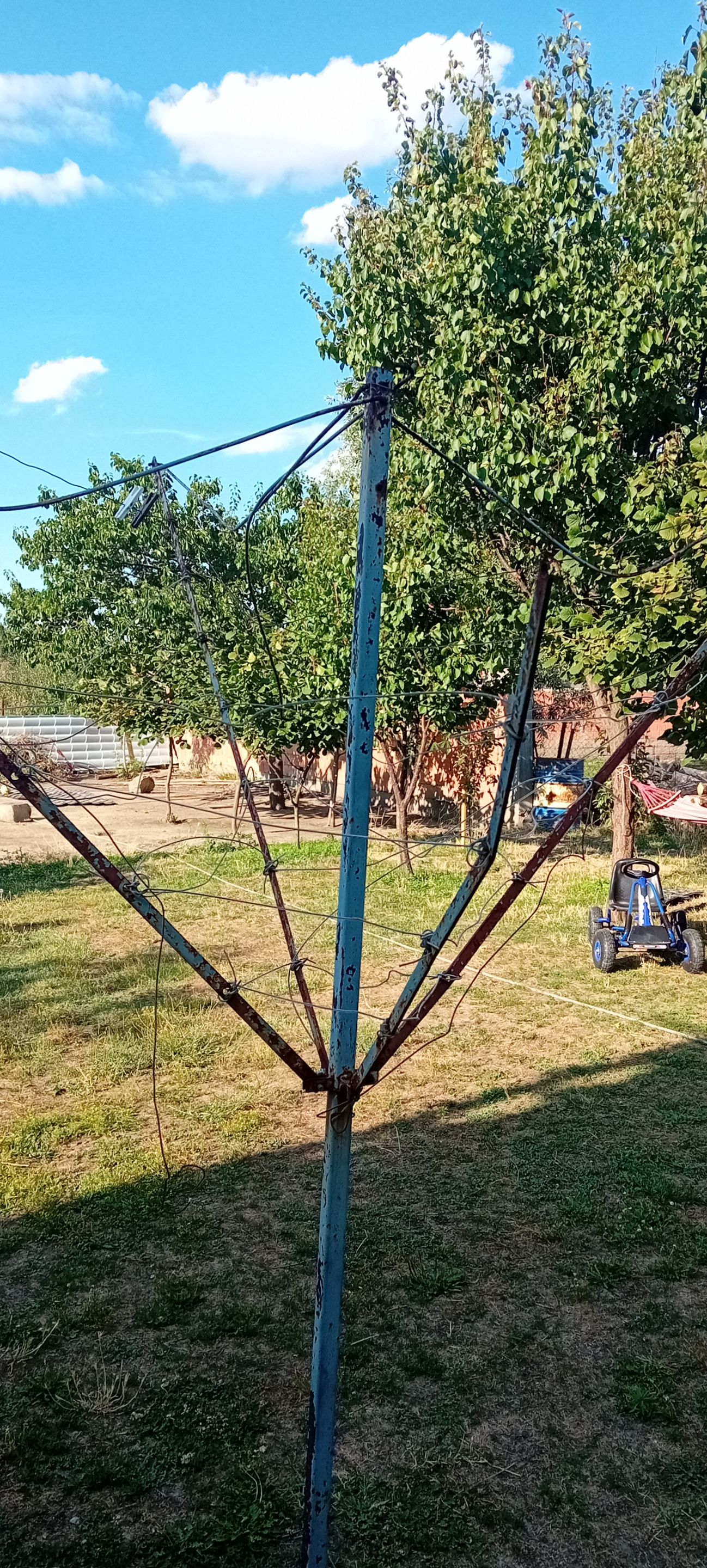

About ten years ago, a friend of mine built me a clothesline. Actually, he did the metal part of the job, I just poured concrete into the tire. Since the tire was our base. There were some mistakes at first, but it was done with what we had. The side bars that held the clothesline bent over time. The millimeter-sized brackets were not strong enough to withstand the gusts of wind. And the rope itself was worn out. Although I have some bigger projects going on right now, I decided to fix this clothesline bracket.

I worked on the conversion myself

I learned to work with various tools needed for household maintenance

I had to remove the old rope and supports

They were to be thrown away

I had to find better and stronger supports this time The choice fell on a square tube with a cross section of 10 x 10 millimeters.

And I added new tie rods for the brackets.

I decided to add the ability to rotate the entire clothesline I was thinking about roller bearings Since this is intended for outdoor use, I would have to make some supports and protection for the roller bearings All of this would have greatly complicated the final production That is why the final choice fell on a metal hinge

For this purpose and conditions, a metal hinge is much more durable and tougher I first welded the metal hinge to a large canvas I cut the main tube of the entire structure in half

And welded a metal hinge.

one part to the main pipe that was left with the concrete base.

and the other part of the hinge to the part of the pipe that I cut.

So now the entire clothesline holder is in two parts.

And welded a metal hinge.

one part to the main pipe that was left with the concrete base.

and the other part of the hinge to the part of the pipe that I cut.

So now the entire clothesline holder is in two parts.

I painted the main metal pole a basic gray color.

I sprayed the welds of the metal hinges and pipes with spray paint.

We haven't actually decided on a color yet, so we're testing it out.

It looks like it's going to be blue.

I threaded the rope through the drilled holes and wrapped it around the support. I used up over 25 meters of rope. When I say rope, I mean the PVC-coated cable.

Thanks for reading. Until next time. Stay healthy.