In the apparel and textile industry, fabric inspection is one of the most fundamental processes that determines the overall quality of garments. Before a fabric roll is sent to the cutting section, it must go through a detailed inspection process to identify defects, maintain shade continuity, and ensure compliance with buyer requirements. Without proper inspection, fabric-related issues can directly impact garment quality, lead to shipment rejections, and eventually damage a factory’s reputation in the global supply chain.

During my internship at Ha-Meem Group, I observed the fabric inspection unit in action and learned about the widely practiced Four Point System for evaluating fabric quality. This method has become a global standard, ensuring consistent and fair evaluation of defects across mills and garment factories.

The Importance of Fabric Inspection

Fabric accounts for nearly 60–70% of garment cost, which makes it the most critical raw material in apparel production. Any undetected fabric defect can multiply once garments are cut and stitched, resulting in high wastage or rejections. For this reason, every leading export-oriented factory in Bangladesh, including Ha-Meem Group, emphasizes systematic fabric inspection before approving rolls for bulk production.

The inspection process generally focuses on:

Detecting weaving, knitting, or dyeing defects.

Measuring shade and shrinkage variations.

Recording the exact quality status of each roll.

Providing clear decisions: Pass, Hold, or Reject.

Common Fabric Defects

During my inspection session, I observed a visual defect board displayed inside the unit. This board helps operators and inspectors quickly identify and categorize fabric problems. Some of the most common defects include:

Knot and Slub – extra yarn entanglement causing thick spots.

Hole and Missing Yarn – visible gaps due to yarn breakage.

Foreign Yarn or Broken Yarn – contamination from different fiber types or incomplete yarn lines.

Thick Yarn and Shading – uneven yarn count or inconsistent color.

Oil Mark, Soil Mark, Stain Mark – stains caused by machine lubrication, dirt, or handling.

Shade Bar and Dyeing Problem – uneven dyeing results.

Weaving Defect, Patta Shade, Miss Print – structural or print-related irregularities.

Damage and End Out – physical tears or roll-end weaknesses.

This clear visualization ensures inspectors follow a standardized defect vocabulary, avoiding miscommunication during quality evaluation.

The Fabric Inspection Process

The practical workflow of fabric inspection at Ha-Meem Group is highly systematic and follows international standards. The steps generally include:

- Roll Placement on Inspection Machine

Fabric rolls are loaded onto a fabric inspection machine, which unrolls the fabric under bright lighting and calibrated measurement scales.

Inspectors carefully monitor the fabric surface as it runs over the inspection table.

- Visual Examination

Using the reference chart for common defects, the inspector marks visible issues such as holes, stains, shade bars, or weaving faults.

- Defect Recording on Inspection Sheet

Each defect is logged on a pre-printed inspection sheet. The sheet contains columns for roll number, yardage, defect type, defect points, and inspector remarks.

- Measuring Roll Length and Width

The actual usable yardage and fabric width are confirmed. This ensures the delivered quantity matches the supplier’s invoice.

- Final Classification

After the inspection is complete, each roll is classified as OK, Hold, or Reject based on its point score and buyer requirements.

The Four Point System

The Four Point System is the most widely used international standard for fabric grading. It assigns penalty points for each defect based on its length and severity. The principle is simple: the larger the defect, the higher the points.

Point Allocation Rules

Defects up to 3 inches → 1 point

Defects up to 3 inches → 1 point

Defects 3–6 inches → 2 points

Defects 6–9 inches → 3 points

Defects over 9 inches → 4 points

Other rules include:

No single defect can exceed 4 points.

Maximum 40 penalty points per 100 square yards is acceptable for most buyers.

Defects are marked and accumulated as fabric runs through the inspection machine.

Practical Evidence from Ha-Meem Group

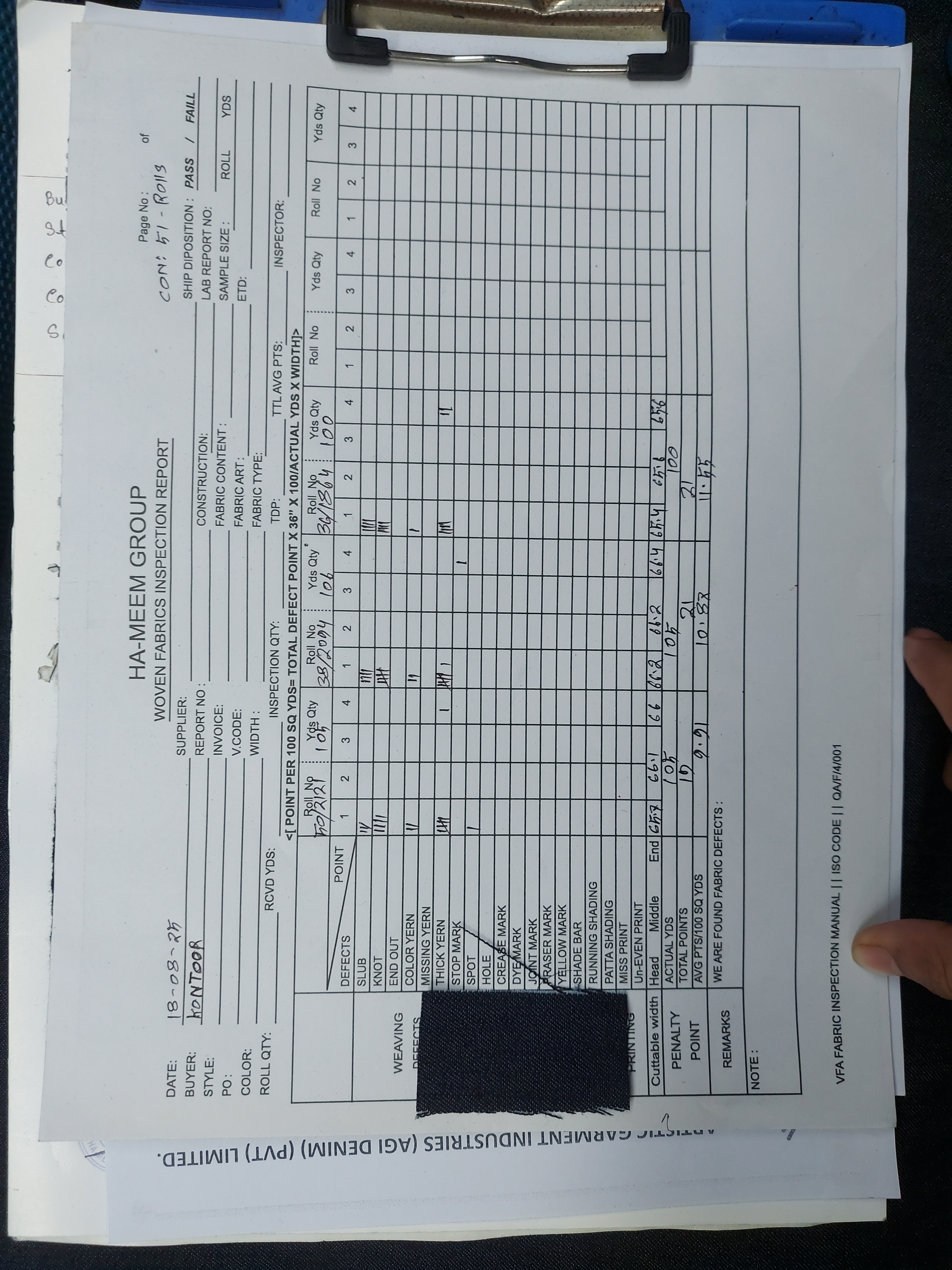

I had the opportunity to review actual Fabric Inspection Reports prepared by inspectors at Ha-Meem. These reports contained:

Roll numbers and received yardage.

Specific defects logged against each roll.

Calculated penalty points as per Four Point System.

Final remarks: Pass, Hold, or Reject.

Alongside, I saw inspectors working on modern fabric inspection machines equipped with measuring meters, bright fluorescent lighting, and defect marking tools. This combination of manual expertise and machine support ensures both accuracy and efficiency.

Advantages of Using the Four Point System

-

Universality – Adopted globally, it ensures uniform communication between mills, garment factories, and buyers.

-

Objectivity – Reduces subjective judgment by inspectors.

-

Efficiency – Quick decision-making for accepting or rejecting rolls.

-

Documentation – Provides traceable reports for buyers and compliance audits.

-

Prevention of Loss – Saves factories from bulk rejection by identifying faulty rolls before cutting.

Reflection from My Internship

Observing fabric inspection in real-time gave me a new appreciation for the precision and responsibility required in this stage. Inspectors must remain focused for long hours, continuously monitoring fabric rolls that often extend thousands of yards. A single overlooked defect could multiply into hundreds of rejected garments.

I also realized that the Four Point System is not just about numbers—it is about building buyer confidence. International brands rely on these inspection reports before approving bulk shipments. As a future professional in this industry, developing strong knowledge of fabric inspection methods will be crucial for ensuring both quality assurance and customer trust. The lesson from today’s experience is clear: Quality in garments begins with quality in fabrics. The Four Point System provides the structured framework that ensures this quality is measured, recorded, and maintained at every stage.