Introduction

As part of my internship journey at Ha-Meem Group, I have entered a new and very important phase: the Bonded Warehouse and Fabric Management System. After gaining insights into washing techniques and dry processes, today’s session gave me an opportunity to understand how raw fabrics are handled, stored, inspected, and finally approved for bulk garment production.

In the apparel supply chain, warehousing and fabric management are often overlooked, but they are in fact among the most critical stages. Without precise inspection and proper storage methods, even the best sewing or finishing sections cannot deliver quality garments. This is why today’s learning about bonded warehouses and fabric inspection procedures felt highly valuable to me as a textile engineer and future merchandiser.

Bonded Warehouse

A bonded warehouse is a secure facility where imported fabrics or raw materials are stored before they are released for production. In the context of Bangladesh’s apparel industry, bonded warehouses are particularly important because most fabrics are imported under special bonded licenses, meaning that import duties are not immediately paid as long as the fabric is used strictly for export-oriented production.

This system ensures two key benefits:

-

Cost efficiency for exporters – since fabrics are exempted from duties, manufacturers can remain competitive in the global market.

-

Strict control of fabric usage – bonded warehouses are carefully monitored, ensuring that every meter of fabric is accounted for, inspected, and used properly.

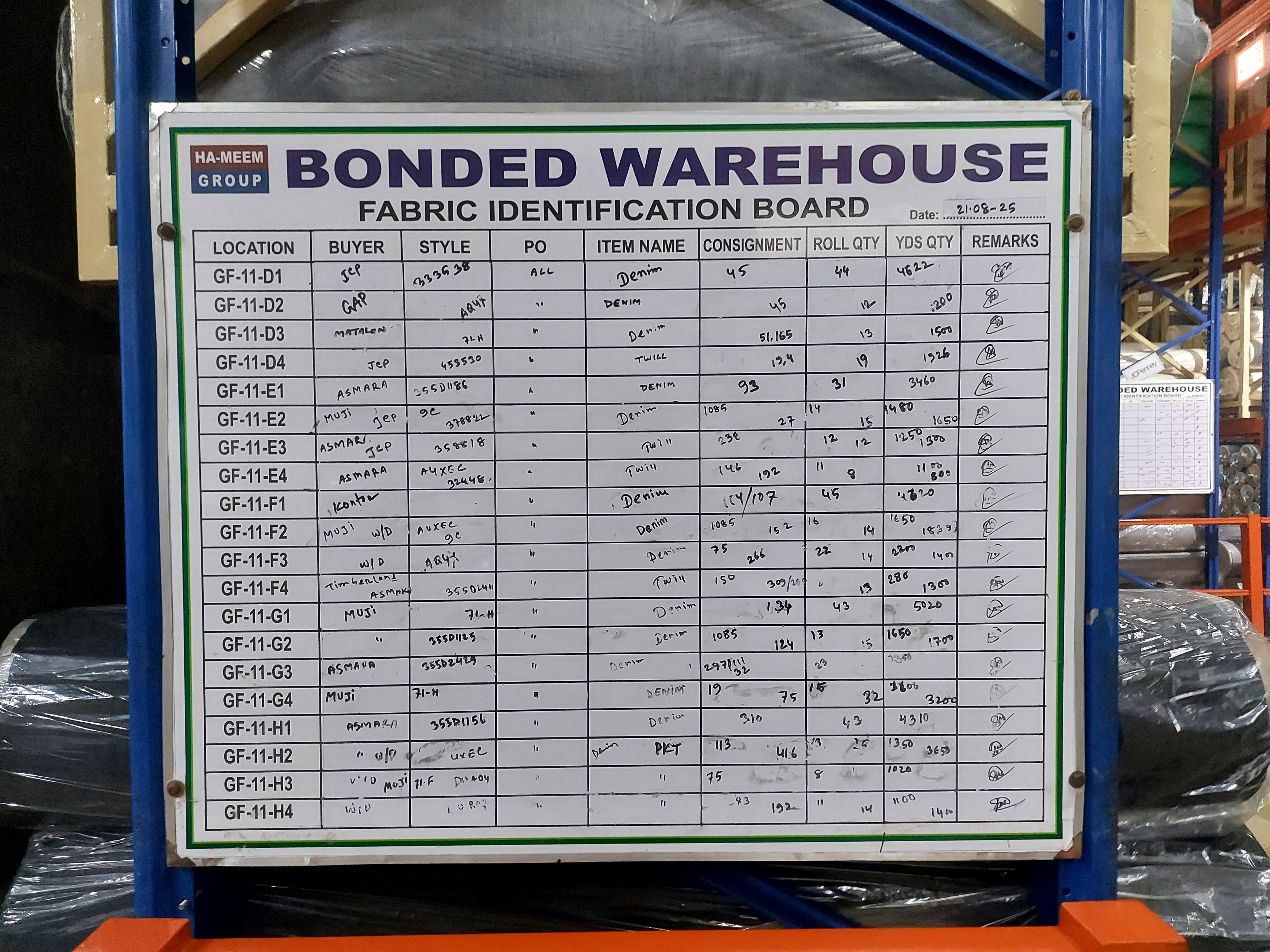

At Ha-Meem Group’s “Creative Collections Ltd.”, the bonded warehouse is managed with structured processes that guarantee fabric quality, consistency, and smooth flow into production.

Fabric Inspection Procedure

One of the most valuable parts of today’s learning was observing the Fabric Inspection Procedure, which is systematically displayed in the factory to ensure compliance and training. The step-by-step process is as follows:

- Fabric In-House

Once fabrics arrive from suppliers, they are received and logged into the inventory.

- Inventory Report

A record is created that keeps track of batch numbers, supplier information, and received quantities.

- Supplier Inspection Report

The supplier’s own quality assurance report is checked against the received materials.

- Approval Lab Dip

Before bulk cutting, lab dips (small swatches dyed to customer-approved shades) are verified to match the required color standards.

- Cut-Able with Check (Cut 6” Beginning & 6” End)

Fabrics are inspected by cutting small swatches from the beginning and end of rolls to check shade and quality uniformity.

- Fabric Inspection (4-Points System)

The international 4-point system is used to evaluate defects such as holes, stains, weaving faults, or shade variations. Each fault receives penalty points, and based on total points per yard, the fabric is accepted or rejected.

- Shrinkage Test Report

Since shrinkage can distort garment fit, this test ensures fabrics remain within acceptable tolerance after washing.

- Twisting Test Report

Fabric twisting (spirality) is measured to ensure that garments maintain shape and do not skew after washes.

- Blanket Making

A “fabric blanket” (a set of swatches from all rolls) is prepared for shade continuity checks.

- Shade & Shrinkage Wise Segregation

Fabrics are separated and categorized based on shade groups and shrinkage levels to avoid mixing during bulk cutting.

- Make Color Continuity Card

Cards are prepared to document shade variations and ensure garments are cut and sewn using fabrics from the same shade group.

- Make Inspection Summary

A final inspection report summarizes the entire batch status, highlighting OK rolls, pending rolls, and rejected rolls.

This process ensures that only the best fabrics are sent to the cutting floor, while defective or non-standard batches are held back, reducing wastage and avoiding rejection from buyers later on.

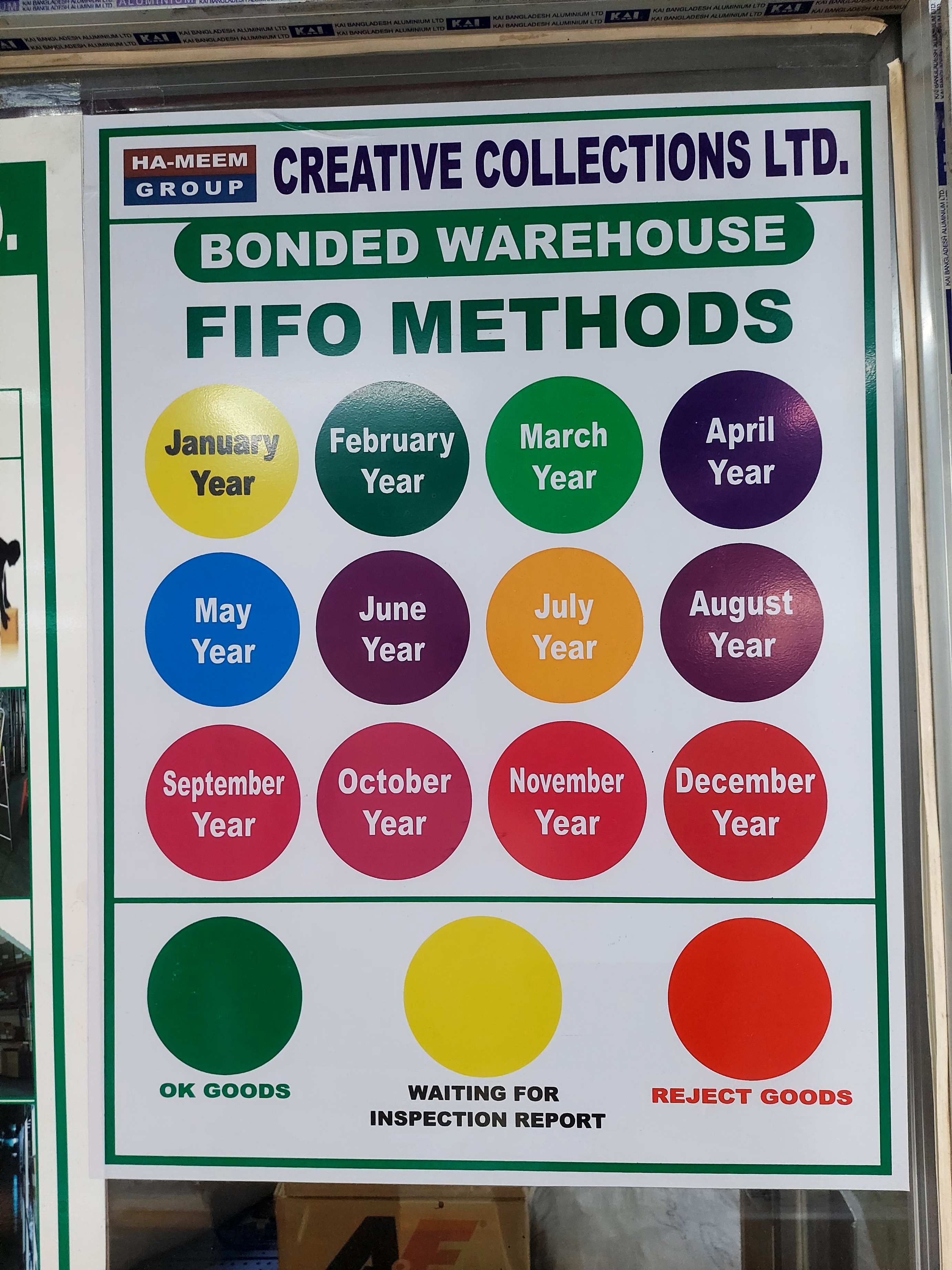

FIFO Method in Bonded Warehouse

Another crucial learning today was the FIFO Method (First In, First Out) used in the bonded warehouse.

This principle ensures that fabrics received first are also issued to production first, preventing old batches from being left unused, which could lead to shade variations, fabric deterioration, or non-compliance with buyer requirements.

The warehouse visually implements FIFO using monthly color codes, as seen in the displayed chart:

Each month of fabric arrival (January, February, March, etc.) is tagged with a different color.

At the bottom of the chart, three indicators show fabric status:

Green: OK goods ready for production.

Yellow: Waiting for inspection report.

Red: Rejected goods.

This simple yet effective system helps the factory floor staff immediately recognize which batches should move first, which need further checking, and which are rejected.

Why Fabric Inspection and FIFO Matter

From a merchandising and production perspective, these processes are not just routine—they are fundamental pillars of quality assurance and timely delivery.

-

Consistency in Shade and Quality – Without fabric inspection and shade segregation, garments in a single shipment could vary in appearance, leading to buyer complaints.

-

Reduced Rejection Risks – By detecting defects early, wastage and costly reworks are minimized.

-

Efficiency in Production Planning – FIFO ensures smooth fabric flow, avoiding delays due to expired or defective batches.

-

Compliance with Buyers – Global buyers demand full traceability of fabric batches. This system provides documentary proof of compliance.

Reflection from Today’s Learning

Today’s exposure to bonded warehouse and fabric management reinforced the importance of back-end processes in garment manufacturing. While many people assume garment production starts at the sewing machine, the truth is that the foundation of quality garments lies in fabric management.

As an intern and future professional, I realized that:

Understanding fabric inspection standards (like the 4-Point System) is vital for communicating with suppliers and buyers.

The FIFO method is not just an accounting principle but a quality control strategy in apparel manufacturing.

My future role as a merchandiser will often require verifying these processes, ensuring that the right fabrics are used in the right way to meet shipment deadlines.

Internship Journey Flowchart

To keep track of my progress, here is the complete internship flowchart we are following at Ha-Meem Group:

Washing → Bonded Warehouse (Fabric Inspection, Bonded Storage) → Cutting → Sewing (Cost Calculation, Garment Method) → Finishing & Packing → Merchandising

So far, I have completed the Washing section and now the Bonded Warehouse section, moving steadily through this structured journey.

Conclusion

Today’s session on bonded warehouse and fabric inspection procedures was eye-opening. It showed me how much planning, inspection, and systematization goes into fabric management before a single garment is even stitched. These are the processes that make or break a factory’s reputation in the eyes of global buyers.

As I continue this internship, I believe these learnings will help me not only gain technical expertise but also develop the mindset required to ensure quality, compliance, and efficiency in every stage of apparel manufacturing.

Connect With Me