Hello everybody!

After completing the four-point inspection system in the fabric section, the next important step I observed during my internship was fabric shrinkage testing and blanket cutting. This stage is crucial because it ensures that the garments we finally produce will retain their intended size, shape, and fit even after multiple washes. Without this step, all the precision maintained in earlier processes could be lost due to unexpected shrinkage in the fabric.

The Purpose of Shrinkage Testing

Shrinkage is one of the most common challenges in the apparel industry. Fabrics, especially denim and woven materials, often contract after washing. If this behavior is not measured and controlled, the final garment may turn out smaller than the intended measurement, leading to customer dissatisfaction and quality issues. To address this, factories use shrinkage tests before moving the fabric into the bulk cutting section.

The process starts with cutting a sample piece of fabric from the inspected rolls. These samples are carefully measured, marked, and then washed under controlled conditions. After drying, the samples are measured again to calculate the percentage of shrinkage. This helps the factory to adjust the cutting patterns accordingly. For example, if a fabric is found to shrink by 2% in length, the pattern will be adjusted to include that allowance before the garment is cut.

Blanket Cutting and Its Importance

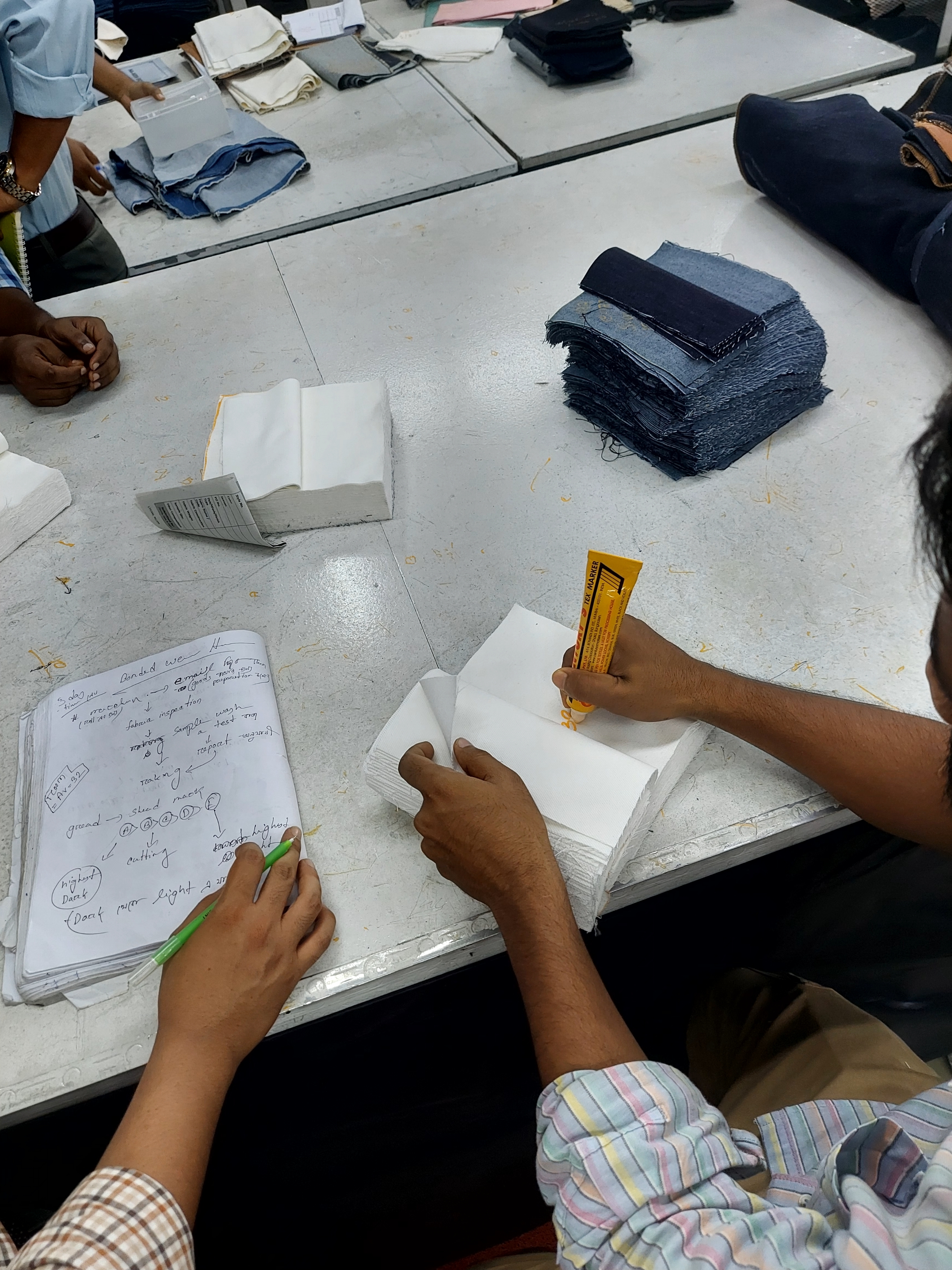

Another important process linked with shrinkage testing is blanket cutting. A blanket is essentially a stack of fabric layers cut together to simulate how the fabric will behave during bulk cutting. By cutting and sewing a small "blanket" sample, the production team can test how the fabric reacts to stitching, washing, and finishing. This step provides vital data on seam puckering, thread performance, and dimensional stability.

During my observation, I saw that workers used a straight knife cutting machine for blanket cutting. This machine, commonly known as the Mack cutting machine, is highly efficient for cutting multiple layers of fabric at once. The operator must wear metal mesh safety gloves to protect their hands from accidents while guiding the fabric during the cutting process. The blade is extremely sharp and powerful, so safety precautions are strictly maintained.

The Role of Cutting Machines

The straight knife cutting machine is widely used in garment factories because of its versatility and speed. It can cut through thick layers of fabric, allowing for high productivity in the cutting department. The machine has a motorized blade that moves rapidly up and down, while the operator skillfully moves the stack of fabric along the desired cutting lines.

In the case of shrinkage and blanket cutting, the samples cut are relatively small compared to bulk production. However, precision remains just as important. Any mistake in this stage could affect the accuracy of shrinkage measurements or cause difficulties later during garment assembly.

Integration with Quality Control

The results from shrinkage and blanket testing are documented and forwarded to the merchandising and quality departments. Based on this data, patterns may be modified, marker plans may be updated, and allowances may be added to avoid size mismatches. This shows how inspection, testing, and production are interconnected in the garment industry, ensuring that every final piece matches customer expectations.

My Learning Experience

Being able to observe this process closely gave me a deeper appreciation of the details behind garment manufacturing. Until now, I had only read about shrinkage tests and blanket cutting in theory. But seeing how precisely the workers handled the fabric, operated the machines, and maintained strict safety protocols was eye-opening. It reminded me that every garment we wear goes through countless small but critical steps before reaching us.

Internship Flowchart Progress

Washing → Bonded Warehouse (Fabric Inspection, Bonded Warehouse) → Cutting → Sewing (All Cost Calculation, Garments Method) → Finishing & Packing → Merchandising

Currently, I have completed:

Washing

Fabric Inspection (Four-Point System)

Shrinkage Test & Blanket Cutting

Next, I will continue exploring deeper into the cutting section and share what I learn.