Well Hello There Fellow Technicians And Hivers!

The Ultimate Break!

So this has been something I see more and more and more everytime I tear one of these "6R80" transmissions!

It's like the people are driving these after they give catastrophic failures! I'd say that's a bit of luck because if it were to happen with me I'd not be able to drive much farther but somehow people manage right!

Whelp, there's a lot of clutch material and even more material coming from the bushes... etc some metal!

Thankfully there is a magnet but the magnet can only grab to something it can attract so pieces of clutch material don't stick which means it all circulates through and that is not something you want clogging up your filters right!

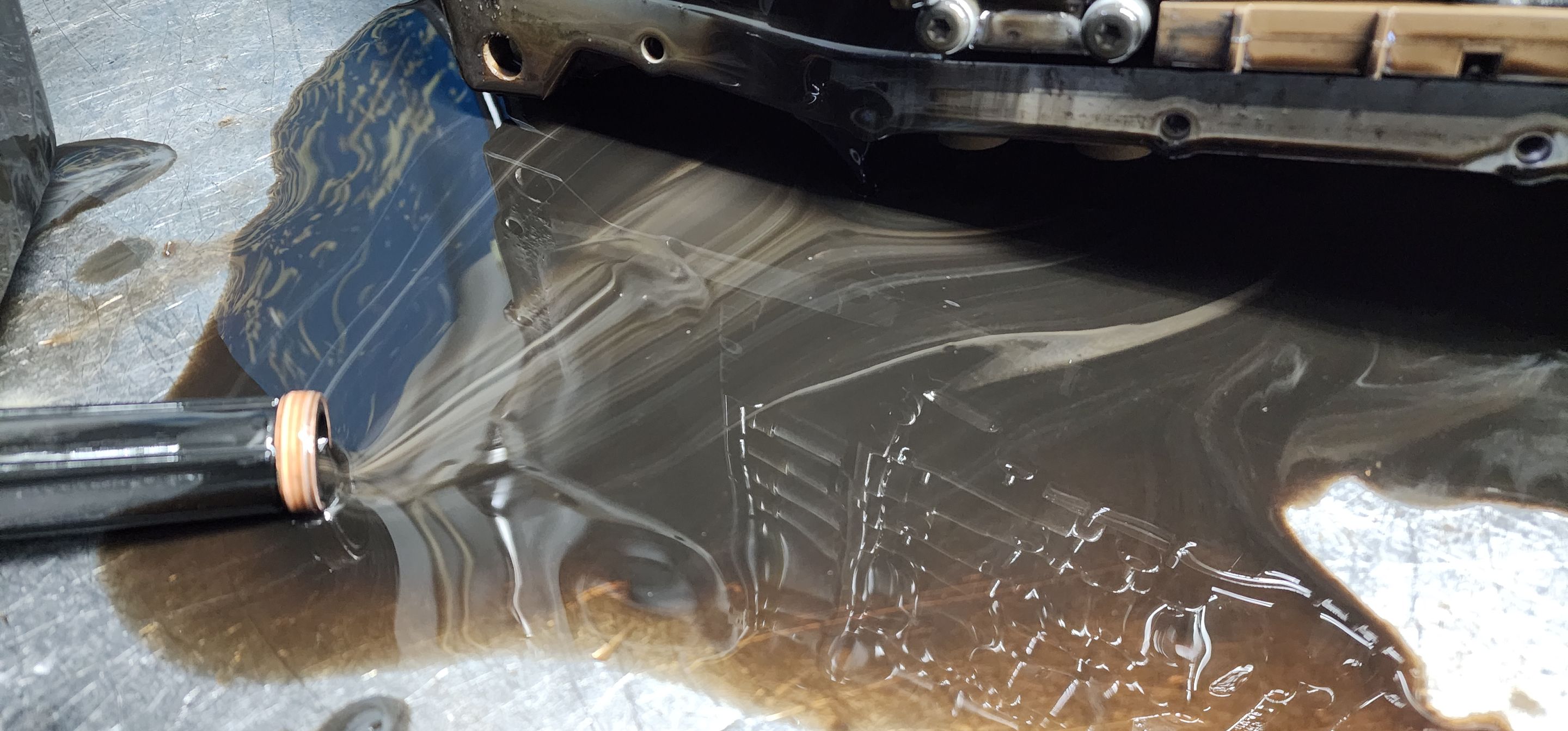

Nasty Stuff!

Well there is some crude oil for you! Yup! Nasty stuff right!?

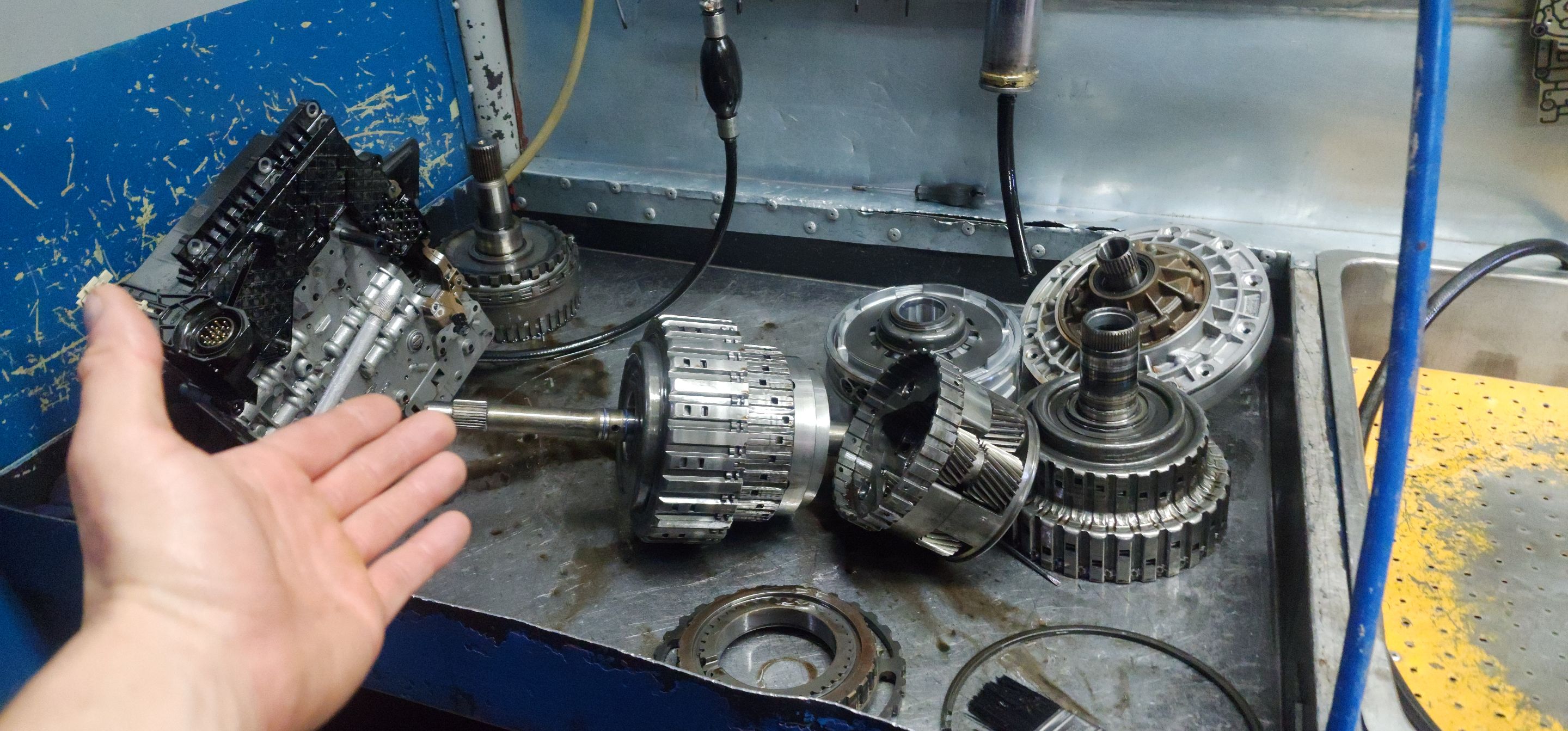

All Torn Apart!

Okay so getting this transmission torn apart is really the easy part! It's legitly no more than a 15 minute job to get everything apart!

The real work is removing and replacing all the bushes and cleaning it!

Now let's do the real inspection!

Only The Hard Parts!

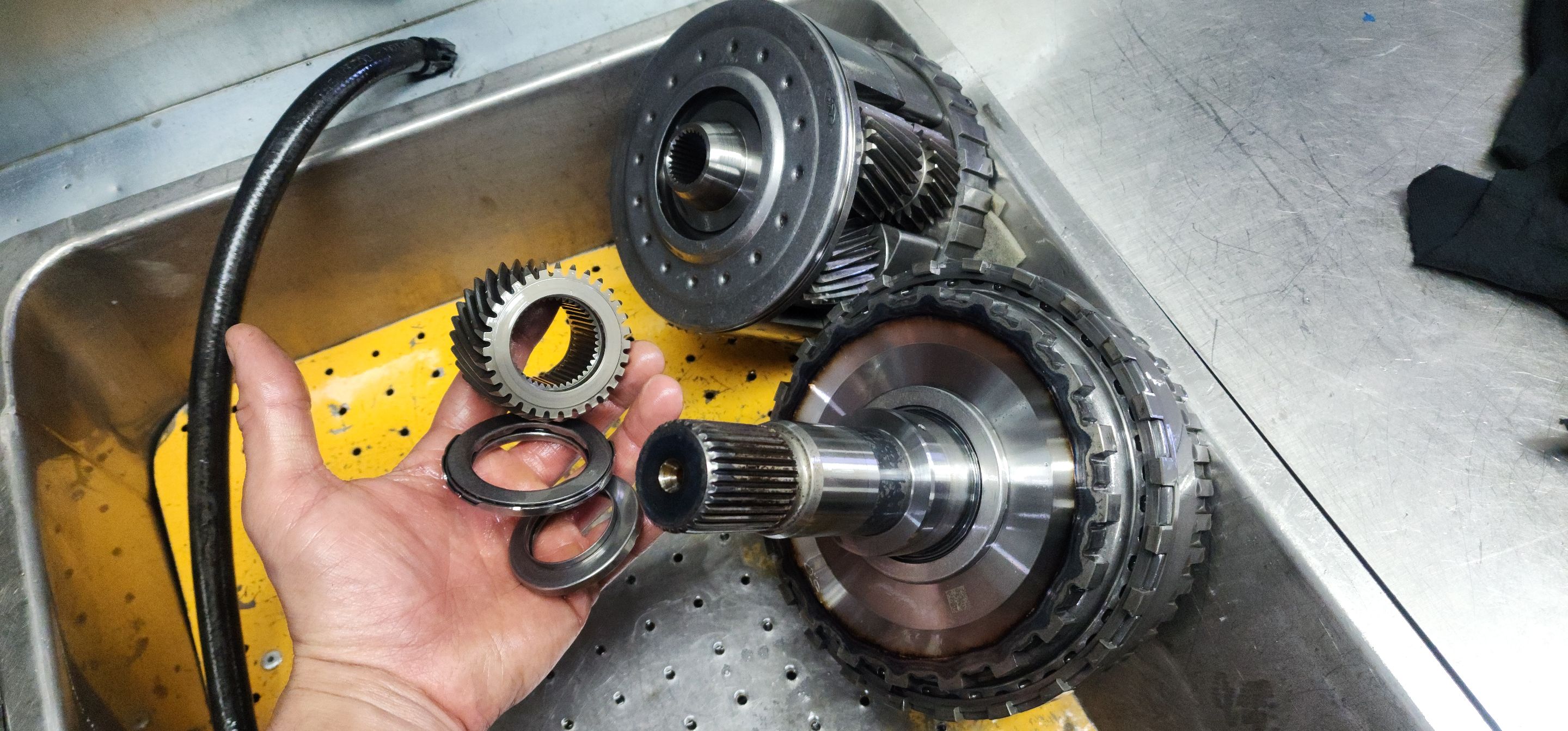

There's some parts that can't be washed in the parafin or anything else for that matter and then there are some parts that can be washed in the paraffin, the hard steel parts are okay, etc the bearings, the gears and the clutch drums and steel friction plates.

However the clutches themselves and everything rubber can't be washed in the paraffin, the reason for this is that the clutch material soaks through with paraffin and that starts to eat off at the material! As for the rubbers, well they also suck in the paraffin and then they start to swell up!

Some of that clutch material really sticks to the steel! A hard thing to get it cleaned out 100%!

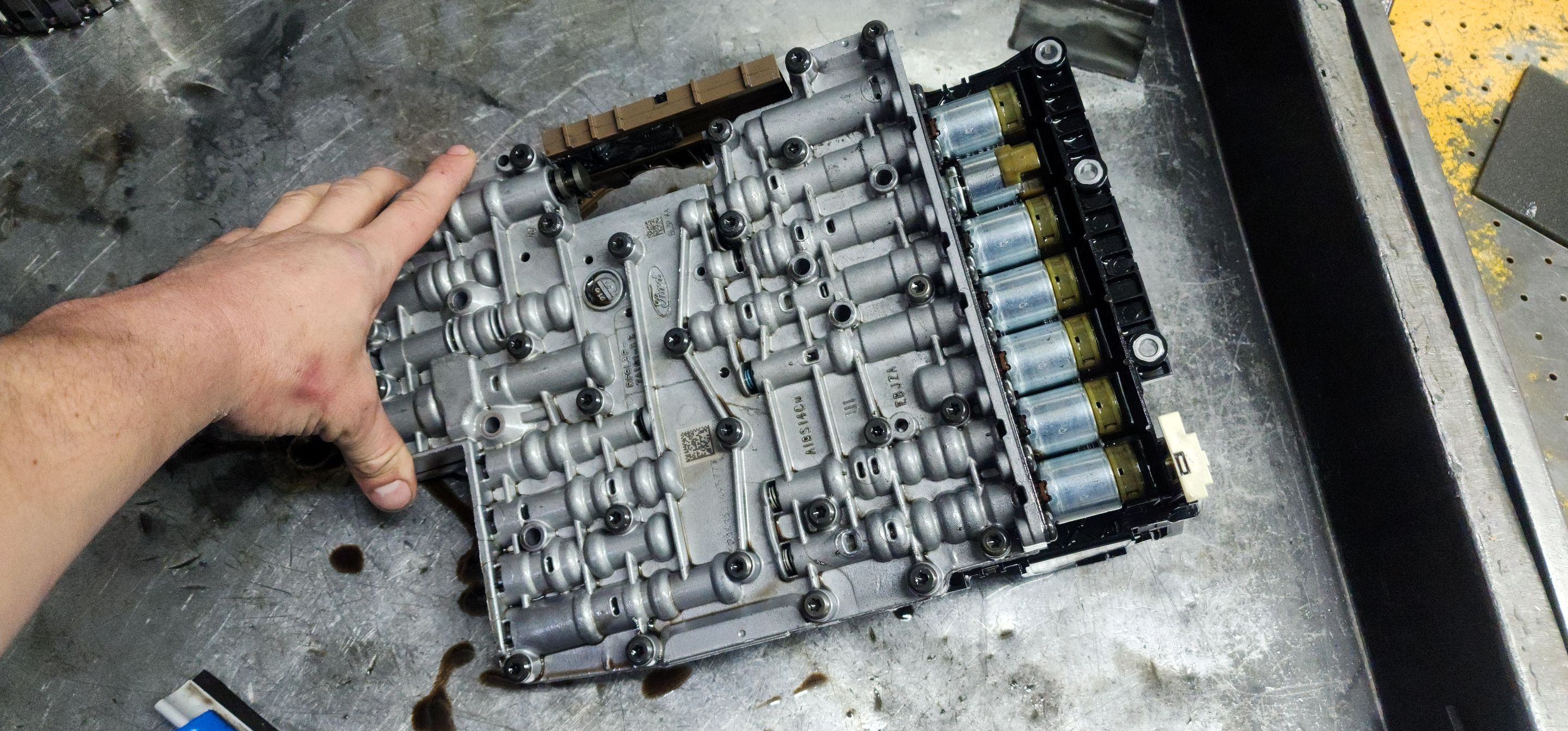

This Is The Real Question!

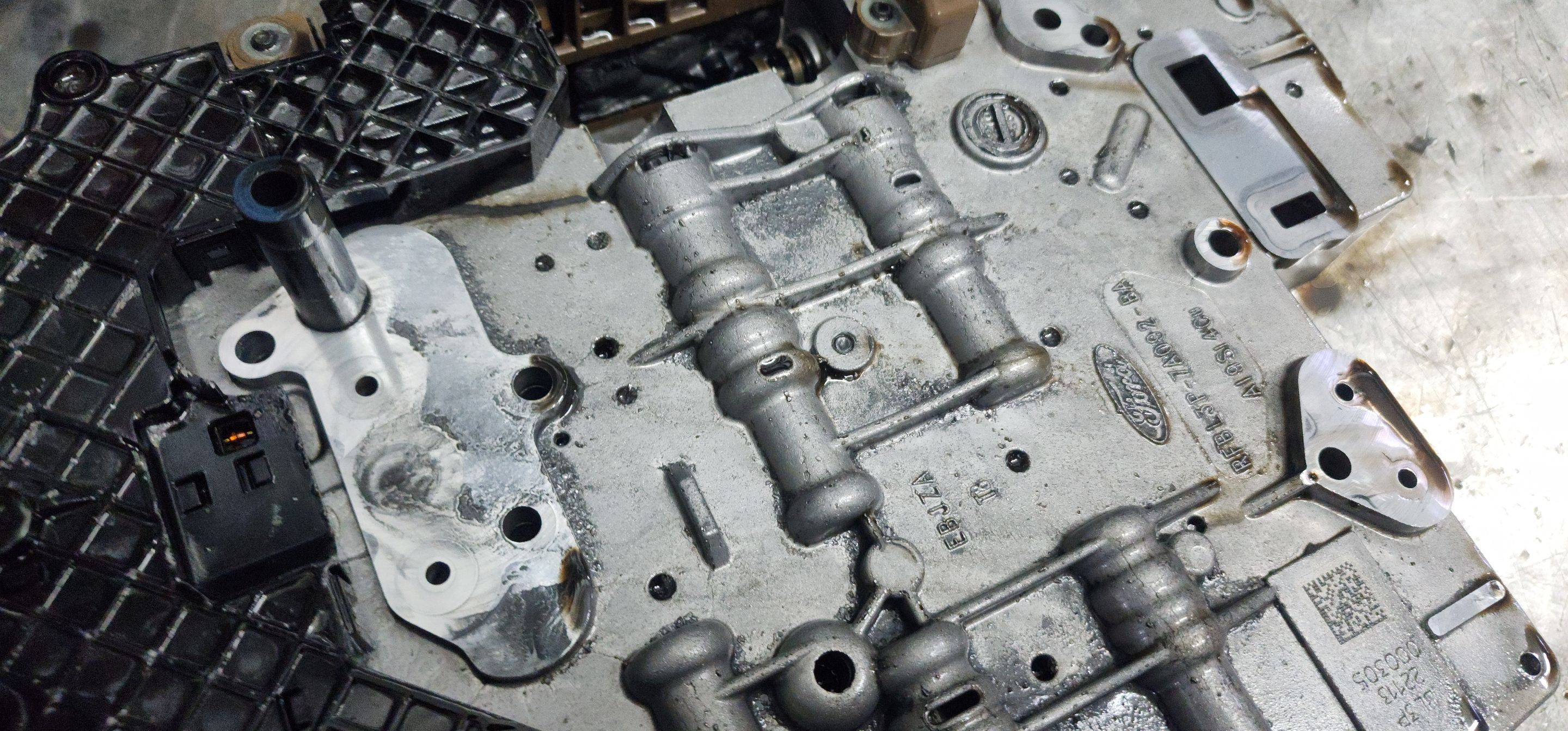

How sure are we that this valve body still works?

Well there is no way for us to know other than to test it! But before we can test it we need to pull this apart too and get this clean times two!

The most effort on the cleaning side goes into these! Sometimes it can be an absolute nightmare!

This Is Why!

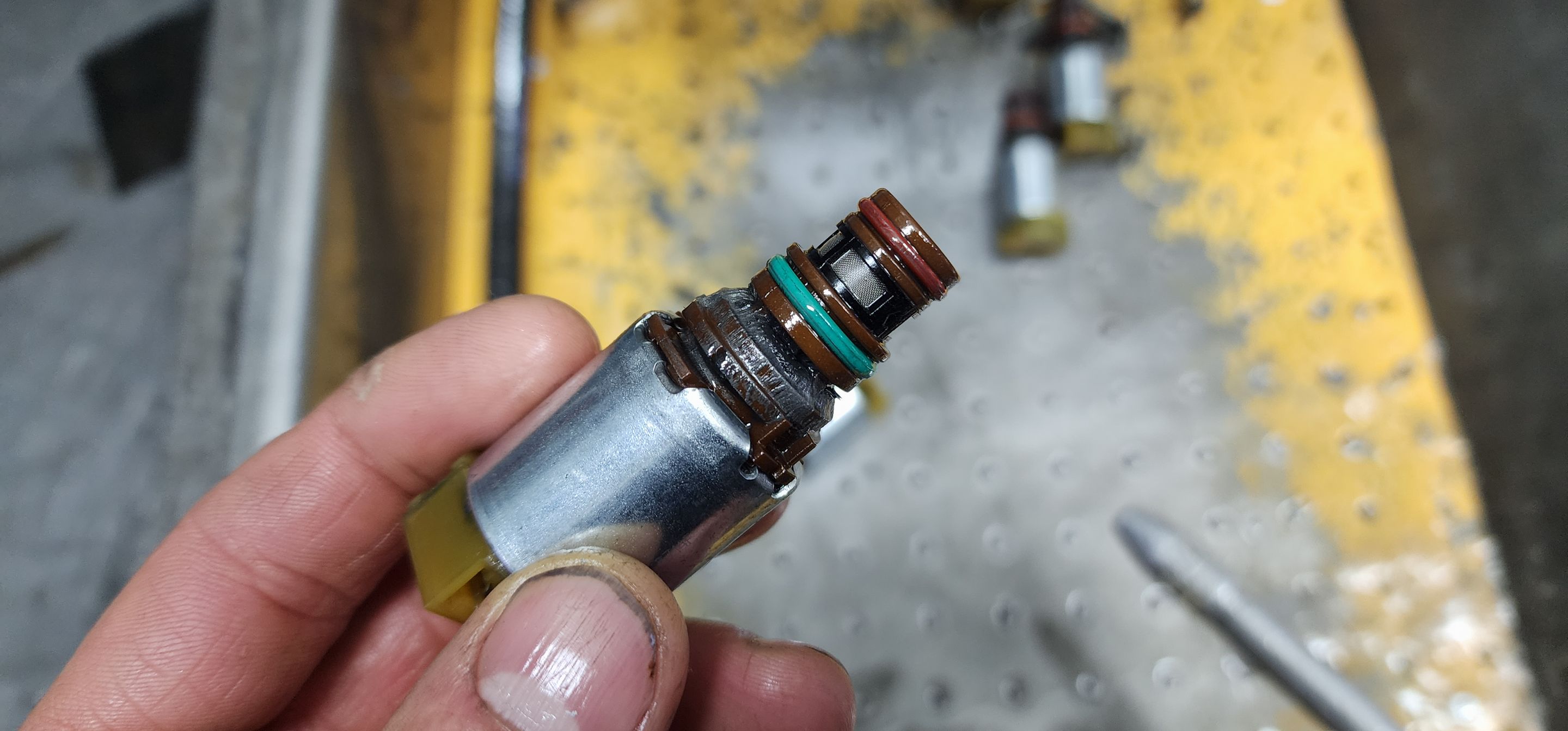

And that right there is the reason we put in so much effort towards the valve bodies!

Remember all that steel and clutch material we spoke of earlier in the post? Yeahp that stuff works through everything! Unfortunately this is the most sensitive part of the entire transmission and that steel works through all the pistons and all of the solenoids!

But sometimes people are lucky and these things come out unscathed, but more than often not!

I mean just taking a quick look at this picture you'd think it's gotten a beating right?

Never thing something as small as a spec can't do anything significant! It can change the entire setup!

Might Need A Swap Here!

Okay so we are going to fit all of the old solenoids back and try to pin point which of them give trouble because I am almost certain that one of them would give trouble!

So this means all of the solenoids will be dumped into a electrolytic bath! Not once but about three times just for the fun of it yes!

The more cleaning the better, that gunk needs to dissapear!

That Took Some Great Effort!

Now I have to be honest here! That right there was effort! To get it to that point in the picture!

Had to tear all the drums apart and clean off every clutch plate individually along with all the steel friction plates and all of the other components! Then I had to visually inspect all of them to see which parts were defective!

Tedious work!

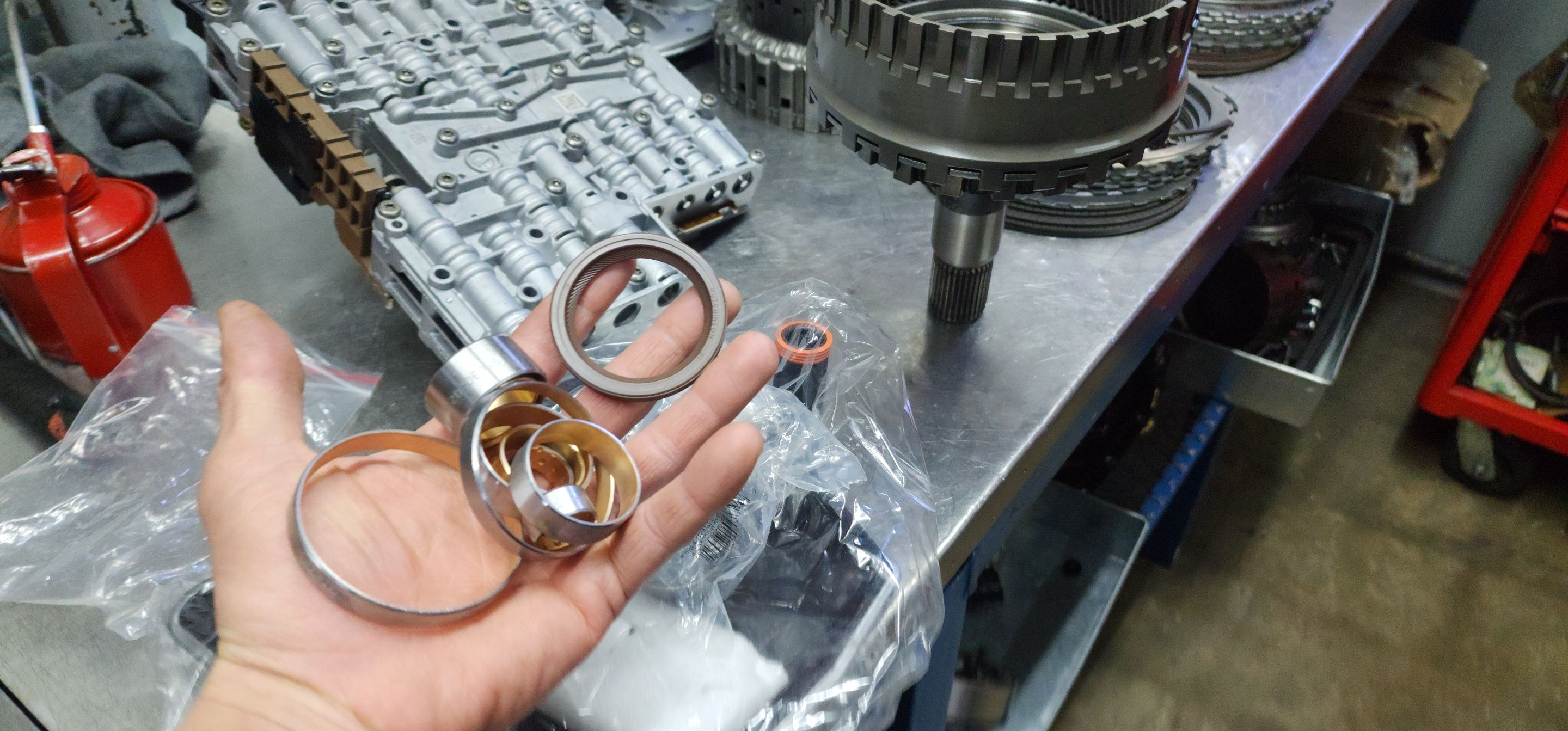

The Bushing Work!

Now for the real work to begin!

YEAH! There is still a great deal of work to be done here!

I have to remove all of the old bushes and fit in new ones! So this requires some hammering of stuff! It is also a little time consuming but it has to be done!

The Natural Thing!

This is natural as can be! Especially after fitting new bushes! Sometimes they are way too tight and has to be shaved off a little!

Only a little, opening up the clearance too much can cause new pressure issues for you!

The Final Assembly!

Well the final drum assembly has been done and now to fit this piece and close it up with the pump!

Yeahp! Now all that is left after this is to get it fitted into the truck and resolve the remaining issues, if any remain at all!

Take note this is not a how to guide, merely myself talking about the work I do and my thoughts around certain things.

To everyone who made it this far into my post Thank you for the read and the support.

If you found this entertaining or educational please consider a re-blog and up-vote.

Most of all please leave a input in the comments below, whether is good or bad critic I would like to know, whether its your opinion or your way of doing things in a different manner I would like.

Connecting the people of #HIVE across South Africa. #hive